Calender

This equipment is used to adjust the surface gloss, hardness uniformity, thickness, and density of base materials by causing them to pass between press rolls arranged vertically or horizontally and applying pressure and heat to them.

Used in combination with line pressure, roll surface roughness, and temperature to satisfy the conditions.

Features

- After assembly, the roll has a runout accuracy of 3 μm or less.

- Compatible with linear pressures of up to 6,500 kgf/cm.

- Reverse-bend device enables deflection correction of the roll in increments of several micrometers.

- The temperature distribution within the effective surface length is ±1 °C.

- The heating method of the rolls can be selected from low-frequency induction heating, high-frequency induction heating, and heat medium circulation.

- We have handled up to 600 °C and 100 tons and can satisfy such requirements.

-

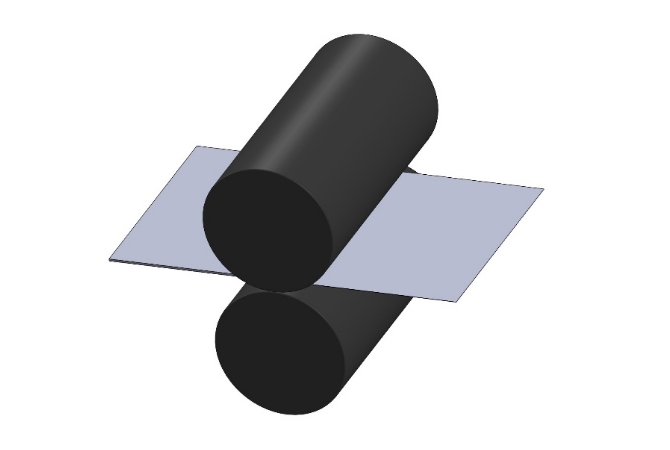

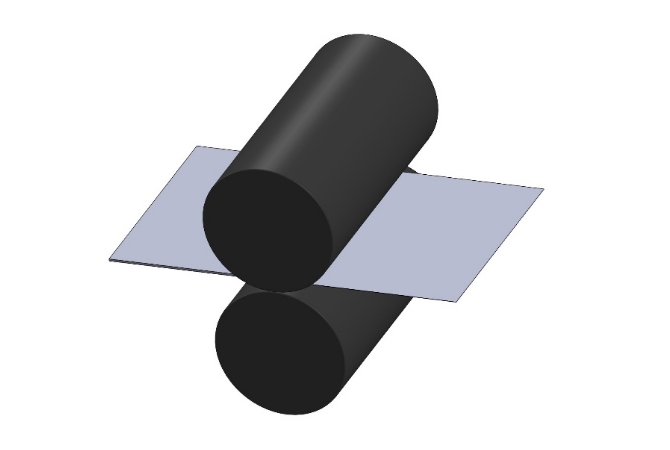

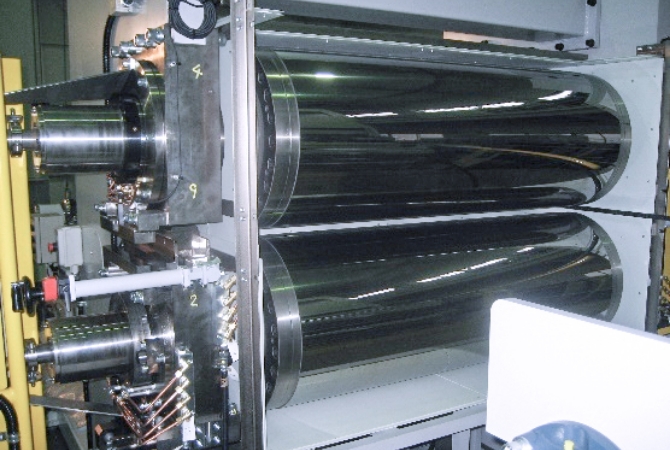

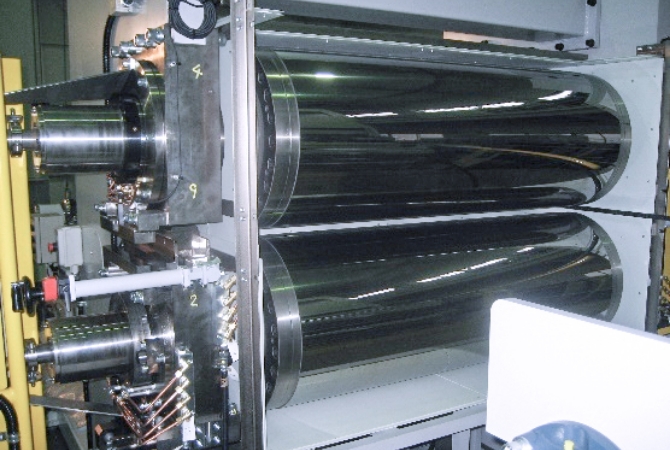

Roll Layout

-

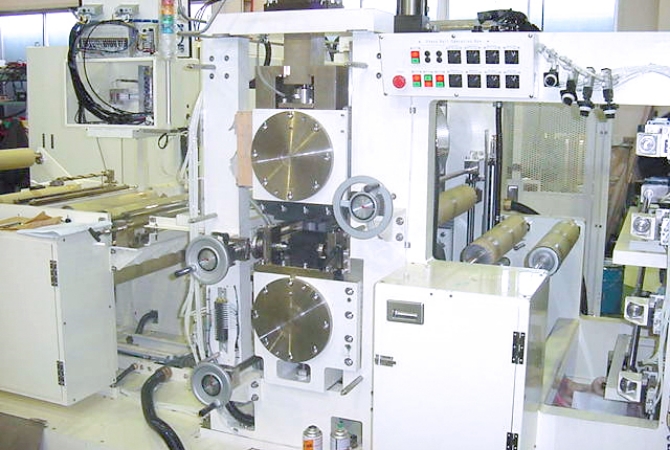

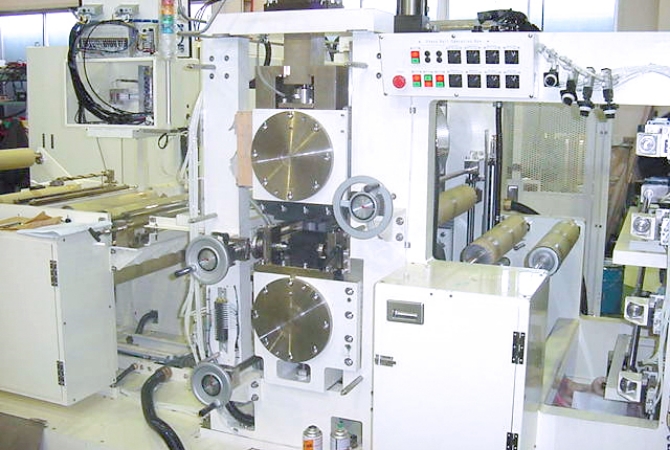

Installation Example

100t-calender

80t-calender

50t-calender

30t-calender

20t-calender

2t-calender