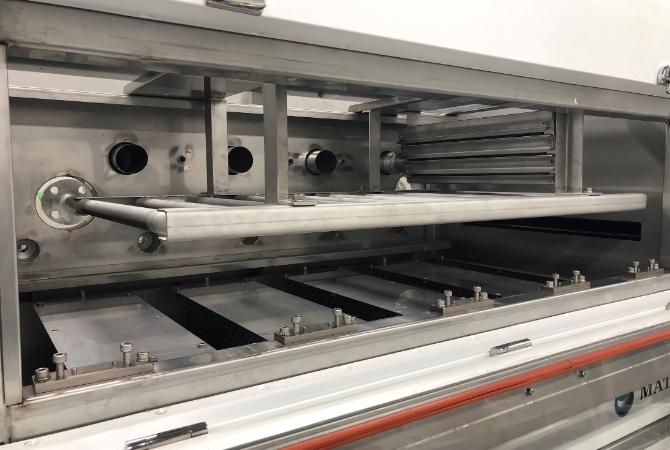

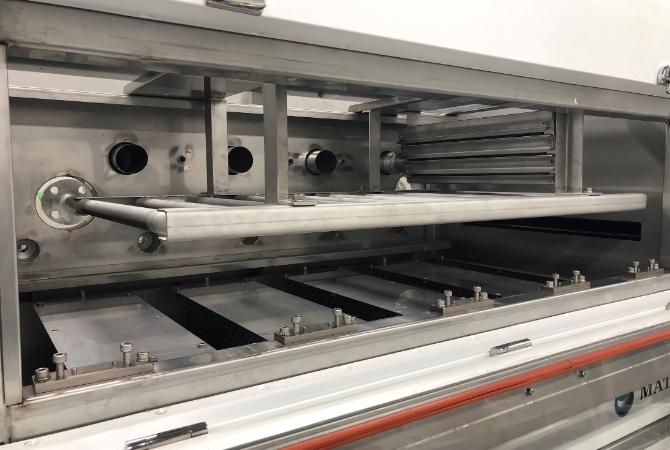

Roll Support Dryer

The method here involves receiving a moving base material with guide rolls and drying the coating liquid on the base material using machines such as a hot-air generator, various nozzles, and IR heaters.

Features

- More stable transportation of the base material is achieved using the guide rolls to receive the base material than using floating nozzles.

- The jet nozzles allow a wide range adjustable air volumes and air speeds.

- The perforated nozzle with a large area of a hot air outlet can produce a large volume of hot air at a low speed.

- The coanda nozzles emit hot air horizontally toward the downstream of the base material, which reduces flapping of the base material even when the coanda nozzles emit a larger volume of hot air than the floating nozzle.

- Counter-flow does not apply hot air directly to the coated surface, allowing gentle drying of the coated surface.

- Compatible with carbon heaters, IR heaters, and other machines.

- Compatible with drying ovens with up to 400 °C.

- Compatible with vertical dryers.

-

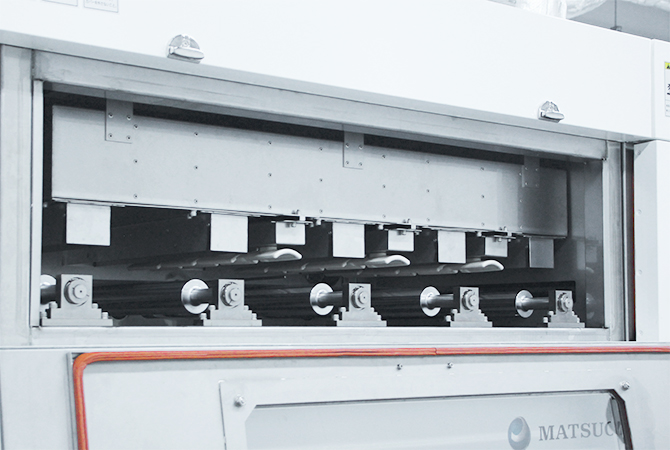

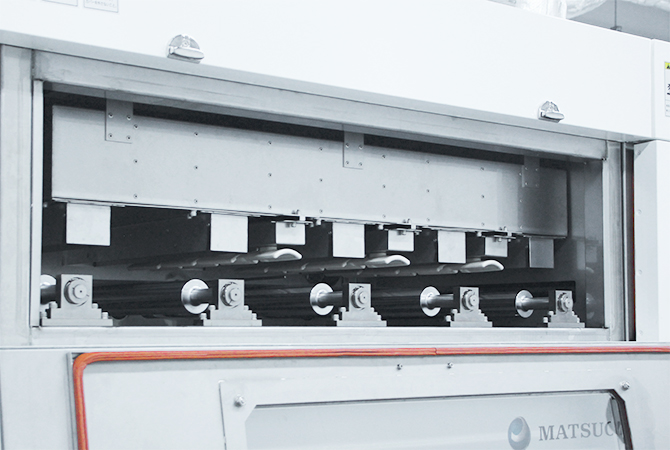

Installation Example

Jet Nozzle + IR Heater

Perforated Nozzle

Carbon Heater

IR Heater

Oil Heaters (Explosion-proof available)