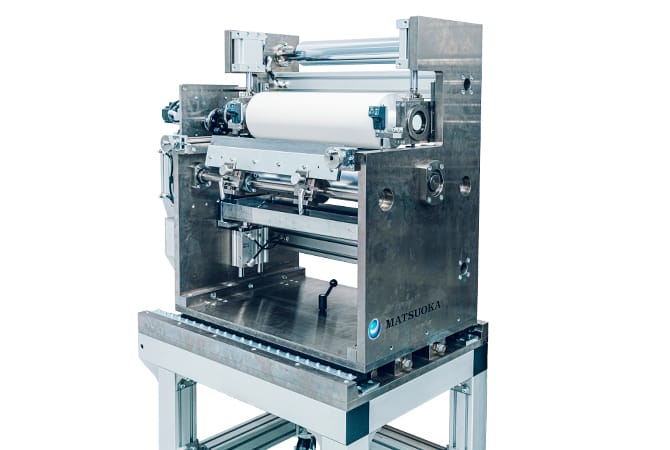

Direct Gravure Coater

Direct Reverse Gravure Coater

The method here involves, with a gravure roll having a finely processed surface and a backup roll for transferring coating liquid to a base material, scraping away excess coating liquid adhering to the raised areas of the gravure roll to decrease the amount of coating liquid remaining in the recessed areas, and transferring the coating liquid to the base material. Coating thickness control depends on the type and depth of engraving on the gravure roll surface. A change in the coating thickness requires you to have several types of gravure rolls with different engraving configurations.

Features

- Can be used for both direct and reverse coating.

- The coating thickness is easily controllable simply by changing the types of rolls.

- Compatible with a variety of base materials

- The coating thickness ranges from 3 to 50 µm (wet).

-

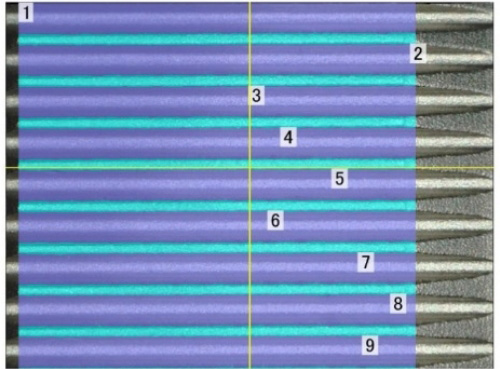

Roll Layout

Direct Gravure Coater

Direct Reverse Gravure Coater

-

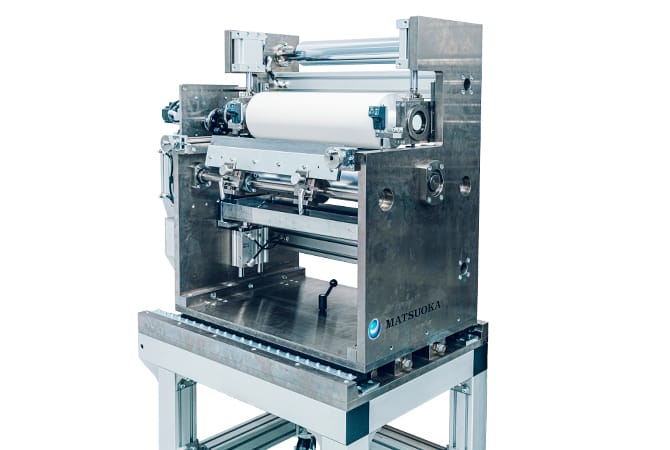

Demonstration Machine

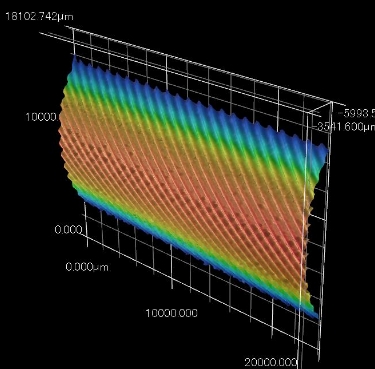

Available Engravings

Oblique

This can be used when the coating liquid is highly viscous and more transferring is required. A doctor blade can be used together.

| Cells/Inch | Depth(μ) | Cell Volume in cm3/m2 |

|---|---|---|

| 35 | 250 | 124 |

| 42 | 190 | 94.2 |

| 60 | 180 | 89 |

| 70 | 114 | 56.2 |

| 70 | 150 | 74 |

| 80 | 130 | 64 |

| 90 | 90 | 44.2 |

| 100 | 77 | 37.7 |

| 100 | 60 | 29.4 |

| 120 | 80 | 39 |

| 130 | 69 | 33.6 |

| 130 | 55 | 26.8 |

| 150 | 55 | 26.7 |

| 150 | 50 | 23.5 |

| 180 | 49 | 22.7 |

| 200 | 35 | 16.8 |

| 230 | 20 | 9.5 |

Trapezoidal

Mainly used in coating with a doctor blade, and has the larger transferred amount than the pyramid type with the same depth.

| Cells/Inch | Depth(μ) | Cell Volume in cm3/m2 |

|---|---|---|

| 45 | 125 | 56 |

| 65 | 120 | 62 |

| 85 | 95 | 46 |

| 102 | 61 | 31 |

| 120 | 64 | 31 |

| 150 | 49 | 22 |

| 165 | 39 | 19 |

| 185 | 52 | 22 |

| 200 | 39 | 15 |

| 220 | 31 | 12 |

Pyramid

Mainly used in flexographic printing and suitable for small amount transferring.

| Cells/Inch | Depth(μ) | Cell Volume in cm3/m2 |

|---|---|---|

| 45 | 254 | 78.5 |

| 65 | 104 | 31 |

| 75 | 98 | 30 |

| 93 | 88 | 25 |

| 102 | 74 | 21 |

| 120 | 53 | 14.5 |

| 150 | 55 | 13.5 |

| 165 | 38 | 8.6 |

| 200 | 29 | 6 |